How can we solve the e-waste problem?

One of the wonders of modern technology is its capacity for upgrade. The software in our cellphones can be endlessly updated. Chips in PCs can be replaced with more powerful alternatives. Laptops can be refurbished; their memories expanded with external RAM. Yet there inevitably comes a day when your beloved device, be it smartwatch, TV, phone or tablet, performs its final service. What was once a trusted and valuable item has become another piece of surplus detritus. What to do with it then?

That question is not merely hypothetical. We have data that shows precisely how, at present, we deal with electronics facing the end of their useful lifespans – and the figures are not always encouraging.

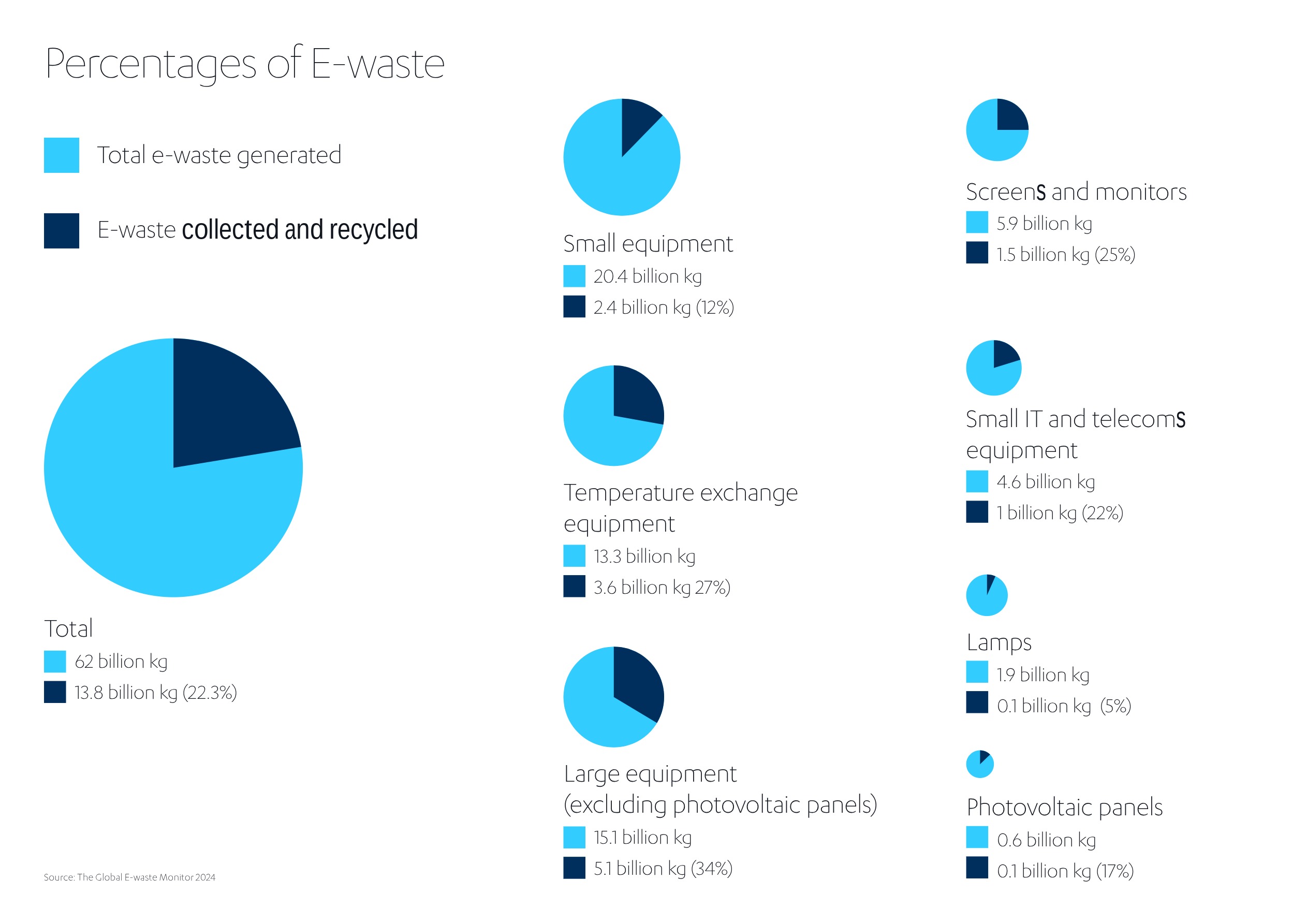

Research shows that we generated some 62 million tons of e-waste globally in 2022, comprising 31 million tons of metals, 17 million tons of plastics, and 14 million tons of other materials.[1]

Less than a quarter of the amount (22.3%) was shown to be successfully collected and recycled, although within this broad analysis are huge variances depending on product type.[2] While white goods (34% reprocessing), heating/radiation kits (27%) and monitor screens (25%) achieve higher rates, smaller gadgets (12%), photovoltaic panels (17%) and lighting equipment (5%) are more prone to uncoordinated disposal.[3]

Left behind are mountains of unwanted electronics: Computers, phones, washing machines, refrigerators, plugs, cameras, microwaves, printers, batteries, sat-nav systems, dialysis machines, medical freezers, and assorted other diagnostic equipment.

What happens to this discarded deluge? Some are dumped on public land or tossed in rivers or seas. Some are needlessly sent to landfill alongside biodegradable waste for burial. Instead of being painstakingly reprocessed component by component, much of this e-waste causes real harm: It is scavenged by underprivileged children in low-middle income countries (LMICs), or openly burned, or bathed in acid, or disassembled by hand, or in the case of plastic coatings, shredded into the kind of microplastics that often find their way into the human food chain. Crucially, little of it is reprocessed and much of it is toxic.

The remnants of our consumer-driven lifestyles carry a heavy environmental toll, and can even directly impact human health. E-waste left to decay can release up to a thousand different substances into our atmosphere and water supplies, including deadly contaminants such as lead, mercury and dioxins, all identified as serious threats to people. And those at greatest risk include some of the most vulnerable members of society.

Who is most at risk from discarded e-waste?

Who is most likely to encounter toxic e-waste or suffer from its harmful emissions? Often it is the poor and underprivileged.

Although most e-waste is generated in developed countries – the USA, Europe, the Far East – much ends up being shipped to emerging economies in Africa and Asia, where reprocessing laws are less stringent. Worldwide, more than five million tons of e-waste was shipped across international borders in 2022, 65% of it undocumented.[4]

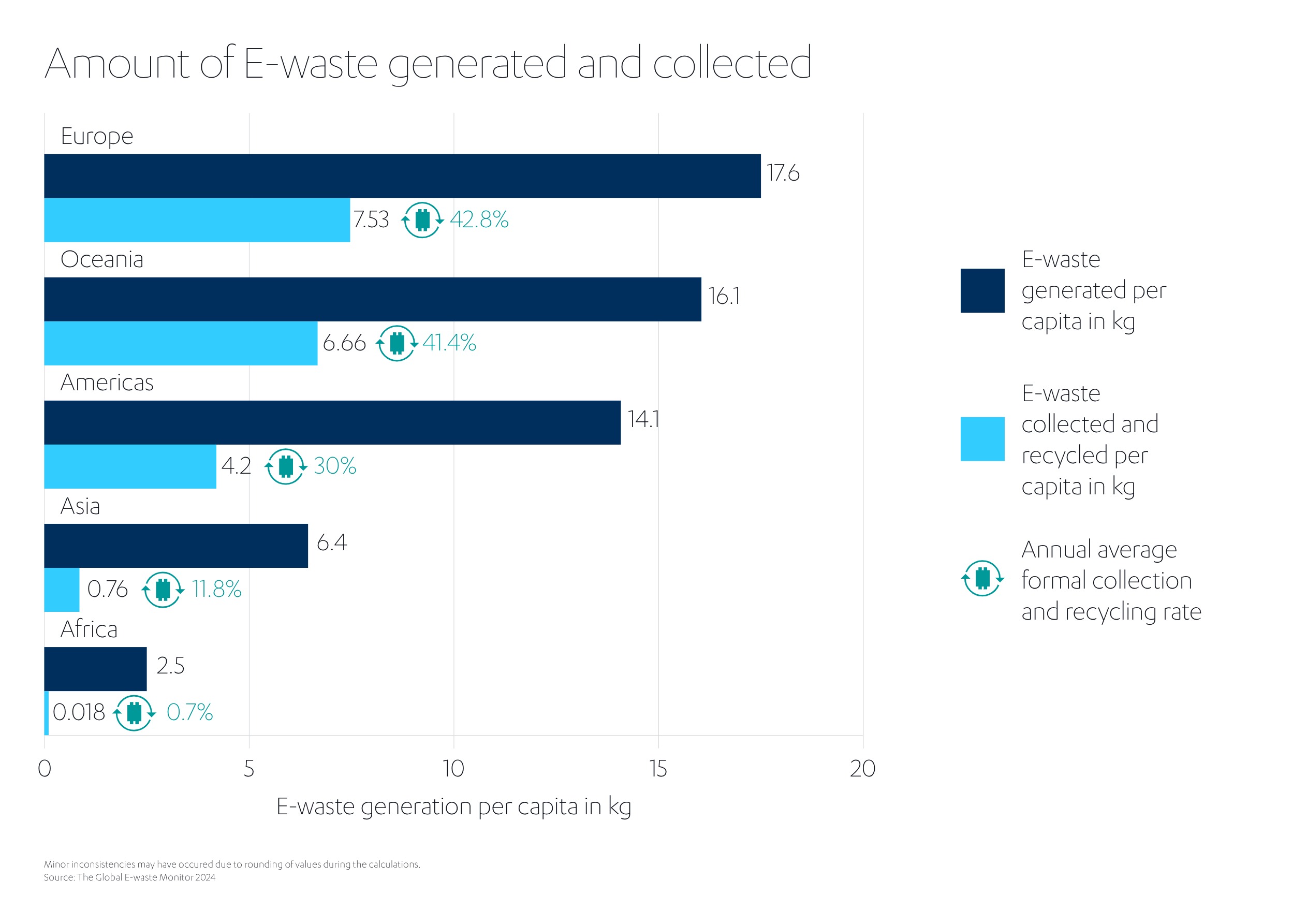

This is shifting rather than solving the problem. Even before accepting other nations’ discarded electronic items, emerging markets struggle to process their own e-waste. Africa and Asia are the continents with the lowest domestic e-waste recycling rates in the world, at 0.7% and 11.8% respectively.[5]

Among Africa’s 54 countries, only 11 have any kind of e-waste policy and just two have designated collection targets.[6] In 2022 it imported more than half a million tons of e-waste, the vast majority of it uncontrolled. In response, some African countries are belatedly embarking on what the UN’s 2024 Global E-waste Monitor (GEM) report calls “awareness-raising initiatives”. Examples include:

- In Tunisia, e-waste treatment facility Collectun D3E Recyclage has joined forces with German international development cooperation agency GIZ on a promotional campaign to entice dozens of local businesses to start recycling their e-waste.

- In Egypt, the Ministry of the Environment is funding the development of a series of e-waste plants to internationally-recognized technological and environmental standards.

- In Ghana, all electronics manufacturers must now pay an ‘eco levy’ to the national revenue authority, which is using the kitty to construct a chain of recycling facilities.

- Nigeria maintains a register of electronic goods manufacturers, charging a fee based on market share and plowing the proceeds into collection and recycling.

- In the Democratic Republic of the Congo, an e-waste initiative at the Benelux Afro Center, operated as an NGO, has already recycled more than 141,000 kg of e-waste. Botswana and Namibia have comparable national e-waste strategies moving from draft to approval stage.

There is similar slow but steady progress under way in Asia. The continent imports almost three million tons of e-waste annually (two-thirds of it undocumented) yet of the 49 countries surveyed in the GEM report, only seven have established collection targets. Several countries are starting to take the problem seriously.

- China, which generates 12 billion tons of e-waste domestically before imports, is gradually introducing a raft of policies to counter the environmental and social impacts. The Circular Economy Promotion Law and the Solid Waste Law outline the appropriate management of e-waste, with a network of licensed recycling facilities being built across the country. Manufacturers are given financial incentives to design products suitable for recycling. Participating companies are experimenting with the commercial aspects of take-back programs, and the challenge of using recycled materials to manufacture new products.

- In Taiwan, the Waste Disposal Act and the Recycling Fund Management Act set targets for recycling rates and enforces penalties for contraventions. Around 31.4% of e-waste in Taiwan is now collected by formally approved schemes.

- Japan’s Home Appliance Recycling Law aims to reach 70% recycling rates for four key household appliances by the end of 2025: Air conditioners, televisions, refrigerators and washing machines.

- Singapore has introduced a reduce, reuse and recycle policy, incorporating a nationwide repair and refurbishment program. It is targeting a 30% recycling rate of internal e-waste by 2030.

With the e-waste burden shared unequally around the world, it is children and women who are suffering most.

Children are a cheap source of labor within LMICs and are often forced into work to provide for their families. The International Labor Organization (ILO) identifies manual waste recycling as one of the most harmful examples of child labor, bringing young workers into direct contact with an array of hazardous substances. ILO figures show as many as 18 million youngsters and almost 13 million women (an unknown number at childbearing age) facing “adverse health outcomes” from e-waste recycling worldwide – all without legal protection or training.[7]

Lead, for example, is responsible for lowering fertility rates among men. It is also associated with blood pressure increases, miscarriages, neurological damage and learning disabilities. Mercury impacts the nervous, respiratory, and cardiovascular systems, and can damage the kidneys, liver and brain. Bismuth causes skin problems and depression, while cobalt can trigger vomiting, eyesight loss, heart disease and asthma. Nickel can promote cancers of the respiratory system. Tin can cause breathlessness and urinary conditions, and zinc has long been associated with birth defects.

Some of the youngest victims are, of course, still gestating in their mothers’ wombs. Chemicals and other dioxins from e-waste have been linked to a greater incidence of premature births and stillbirths, along with stunted brain development and compromised respiratory, immune and central nervous systems. The result is shorter and more limited lives – a true toxic legacy.

And disturbingly, the problem may yet get worse.

Bounty of precious minerals being left to decay

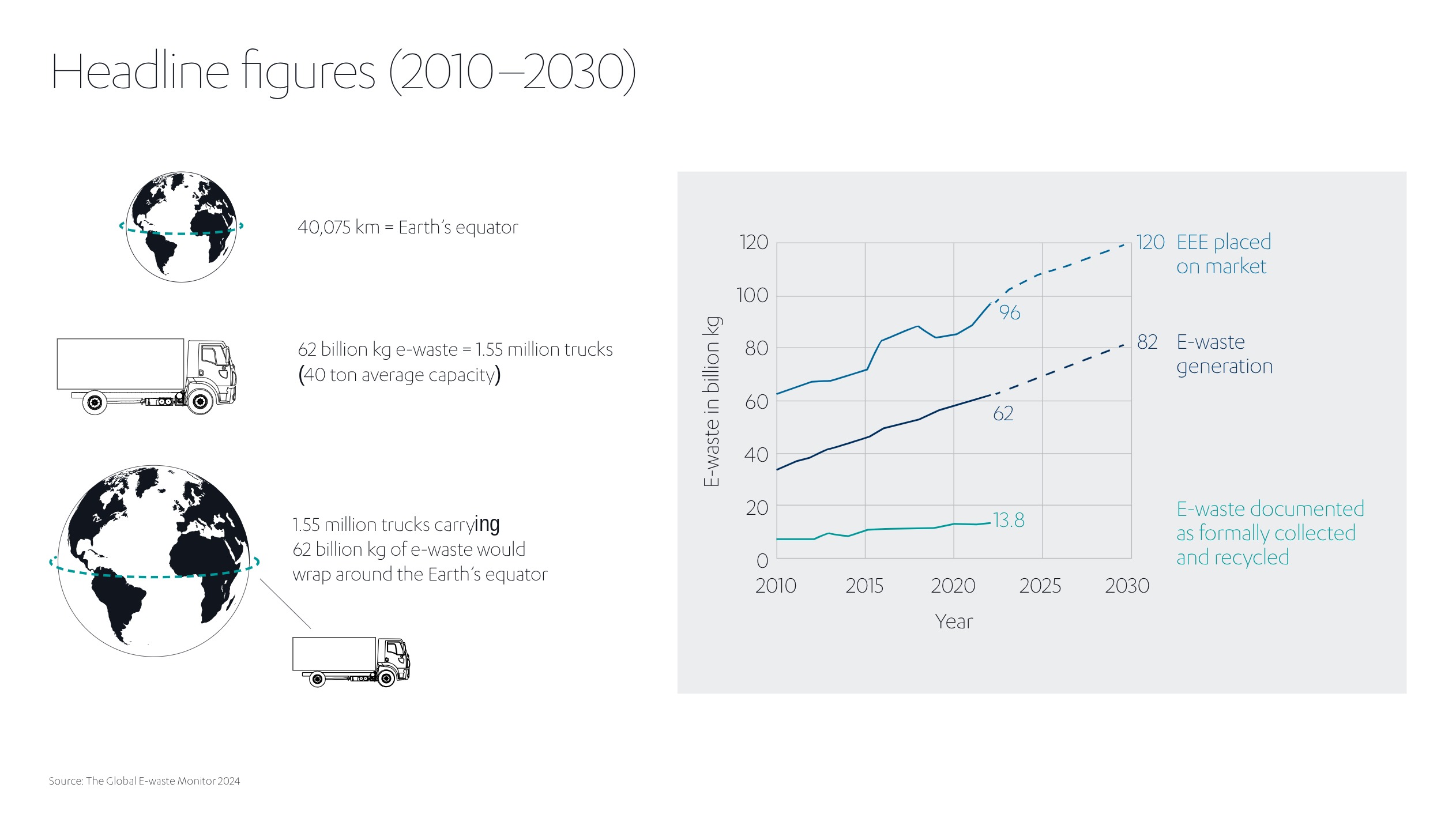

The 62 million tons of e-waste newly produced in 2022 marks a sharp increase from the 34 million tons recorded in 2010. This trajectory shows no sign of altering, with 82 million tons of e-waste anticipated annually by the end of the decade, a further 33% rise on the 2022 figures.[8]

These trends should perhaps not be surprising, given that the amount of new electronic electrical equipment (EEE) manufacturers are unleashing upon the global market is growing steeply. Whereas some 96 million tons of new EEE found its way to shops and stores in 2022, by 2030 this number is expected to rise to 120 million tons – a 25% increase in less than a decade.[9]

This disproportionate growth in new EEE will likely herald a decline in the overall e-recycling rate, from an already inadequate 22.3% in 2022 to an even more slender 20% by 2030. No one is suggesting that this signals a conscious decision on society’s part to downgrade the problem of e-waste; it is just an indication that we are generating far more EEE than we can ever hope to reprocess under our current recycling regime.

Perhaps, however, we underestimate the financial incentive. More details are constantly emerging about the astronomical value of materials lying dormant within the items we so recklessly discard.

In 2022, alone metals worth approximately US$ 91 billion were dumped within the mass of e-waste produced. That figure included an estimated US$ 19 billion of copper, US$ 16 billion of iron and US$ 15 billion of gold. Presently we barely scratch the surface of extracting maximum returns from this bounty-in-waiting.

Some US$ 28 billion of secondary raw materials are sourced each year via e-waste processing. Beyond the financial impact, every kilogram of reclaimed minerals also benefits the ecosystem. According to calculations, repurposing raw materials for secondary use avoids the extraction of 900 million tons of fresh ore annually. With mining causing around 7% of deforestation in developing countries[10] – and with rare Earth metals becoming ever-more prized assets – we should not be lacking motivation to readdress our relationship with e-waste.

Given these stakes, how can we set about drastically increasing the amount of e-waste we recycle worldwide?

Should manufacturers take more responsibility for e-waste?

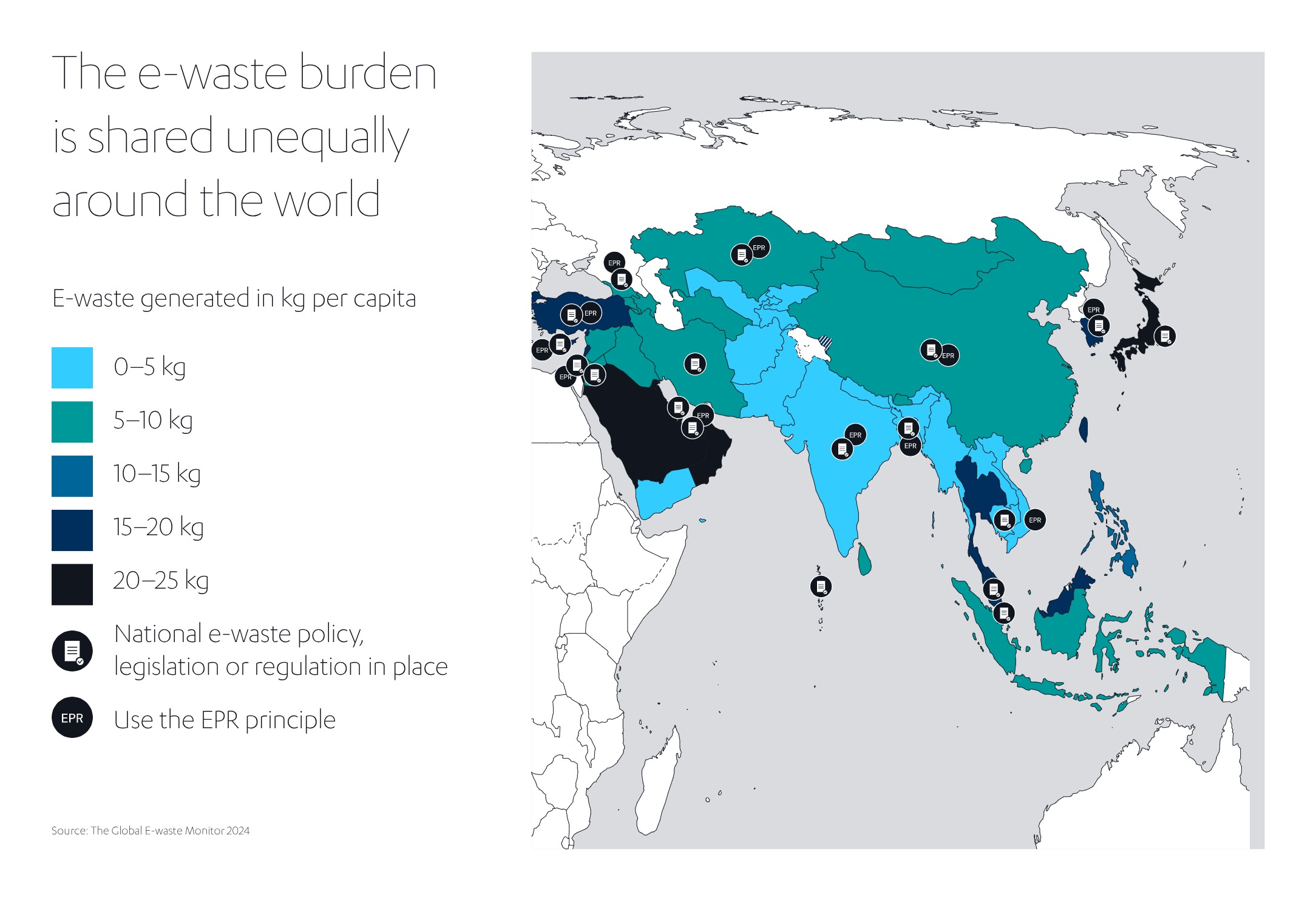

In recent years several countries have been busily evolving policies, of varying effectiveness, to counter the impacts of e-waste. However, of the 195 countries recognized in the world today just 81 have adopted any kind of e-waste legislation. Around a third (67 countries) have defined legal provisions for Extended Producer Responsibility (EPR) laws, shifting the reprocessing burden back on to the original manufacturer. Around a quarter (46 countries) have specified goals for e-waste collection rates.[11]

It’s a good start. But I firmly believe we can, and must, go further and faster.

The UN Global E-waste Monitor (GEM) report laments the fact that even among countries with e-waste policies, few have set targets for repair and redistribution.[12] This bias towards recycling over reuse fails to hasten our transition to a circular economy, perhaps because it reinforces our traditional consumption-disposal economic model.

However, change is potentially coming. In the USA and the EU, for example, progressive legislators are developing rules governing EPR obligations and ‘right to repair’ laws. This latter concept – making products more fixable and ensuring easy access to spare parts – represents a rare public-sector intervention on the design and production of consumer goods.

In the EU, Waste from Electrical and Electronic Equipment (WEEE) rules are designed to support the retrieval of secondary raw materials. They encourage the individual collection and treatment of e-waste, while setting minimum targets for recovery and recycling. Legislators also hope to combat illicit waste export by making it more difficult to hide under-the-radar shipments. The rules also lay the groundwork for national EEE registers to eliminate any unnecessary administrative costs and make the whole process more economically attractive.

Similarly, the EU’s recent Ecodesign for Sustainable Products Regulation (ESPR) mandates a ‘digital product passport’ to enhance the green transparency of electronics. By sharing detailed product information between all stakeholders, it aims to further promote circularity as a viable concept.

In the USA piecemeal efforts are emerging at state level to refine the treatment of electronic products, encompassing both e-waste and its associated packaging.

Currently 26 states as geographically diverse as New York and Alaska have introduced e-waste laws driven by EPR principles. New rules, covering everything from computers and consoles to telecommunication devices, compel manufacturers to join approved collection programs. Penalties per violation can reach US$ 1 million.

Meanwhile, a further 21 states have introduced EPR laws around packaging, with fines of up to US$ 50,000 per infringement. California’s Plastic Pollution Prevention and Packaging Producer Responsibility Act, and Minnesota’s Packaging Waste and Cost Reduction Act, are among the active bills placing the onus of responsibility for a material’s fate on a combination of manufacturers, wholesalers and retailers.

But can lawmakers ever hope to keep pace with the avalanche of e-waste constantly being created? In 2020 the UK’s Environment Audit Committee released a report saying British homes each had an average of 20 unused electronic items.[13] In 2024 the committee accused the government of making little progress in tackling the issue and failing to grasp the scale of an “e-waste tsunami”.[14] Promisingly, the UK is in the process of introducing new laws forcing online retailers to ensure all EEE complies with UK waste laws, and requiring manufacturers of such goods to include predicted product lifetimes on all packaging.

The success or failure of such initiatives matters. Other global regions at an earlier stage of their e-waste journey, such as Africa and Asia, will be watching with interest and may look to deploy the most effective strategies domestically.[15]

Could new technologies help to solve the e-waste problem?

Legislation could provide a blueprint for changing our attitude to e-waste, but it does not guarantee mass adoption. Reprocessing e-waste is difficult, time-consuming and not always commercially viable.

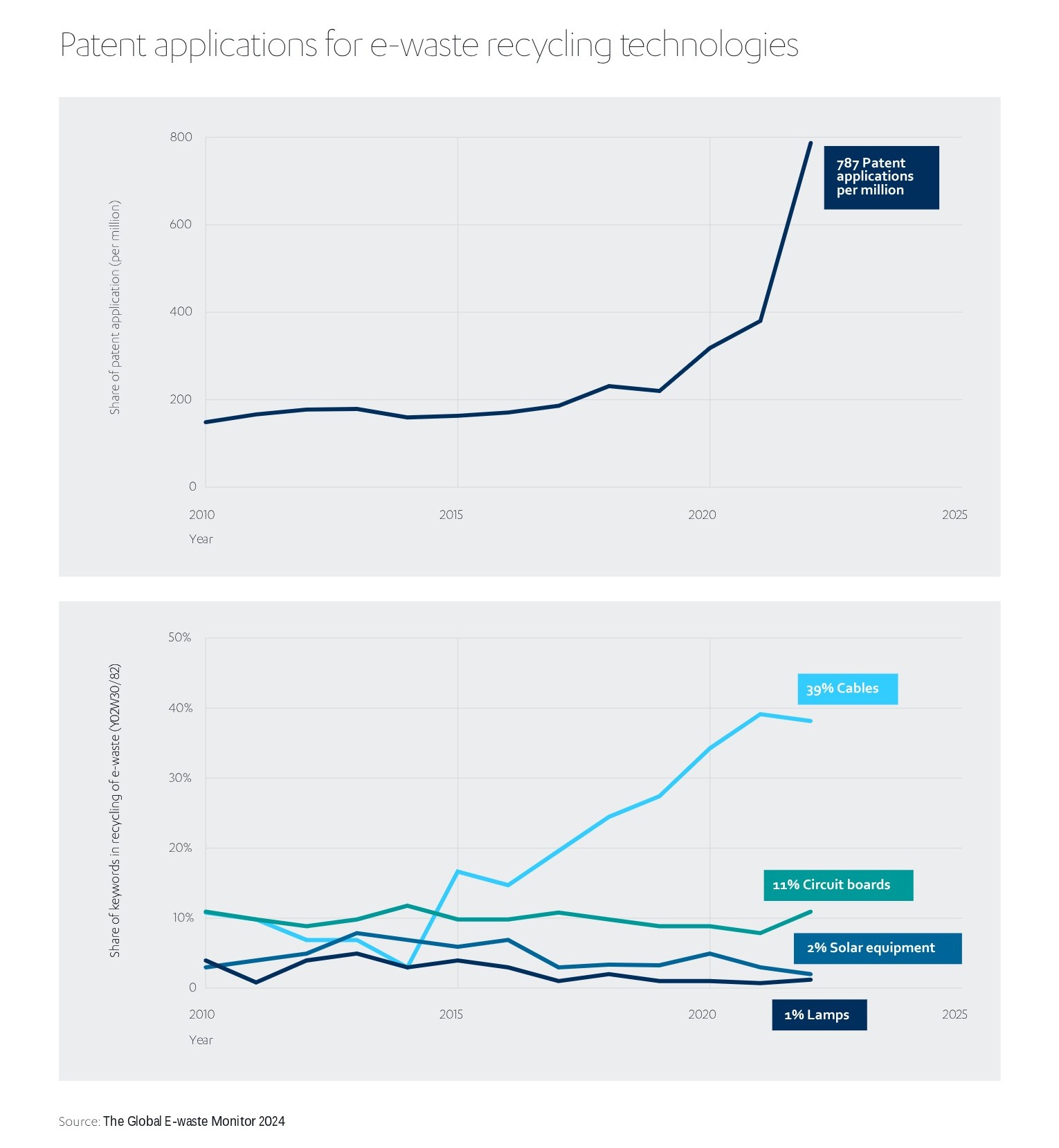

Technology could hasten the process, but game-changing breakthroughs are slow to emerge. A casual analysis of emerging e-waste technologies suggests a flurry of recent innovations, with the proportion of e-waste patent applications reaching 787 per million by 2022, up from 148 per million in 2010. However, a deeper analysis of these applications shows that almost four-in-ten were exclusively concerned with the reprocessing of cables. Technologies for extracting precious metals from circuit boards, solar equipment and lamps remained fairly stagnant during that timeframe.[16]

There are technologies on the horizon that offer a glimmer of hope, however.

Firstly, we can look to the potential savior of artificial intelligence (AI). The latest generation of camera-equipped AI can identify and sort electronic materials with a precision far exceeding existing machinery, with an accuracy rate of 99% and a 50% boost to productivity.[17]

New chemical recycling techniques are also being developed which are capable of breaking down mixed-material substances into their individual chemical components. That could mean less new plastic being needed in future, as well as previously unrecyclable items becoming fit for processing.

A new wave of metallurgy technologies promises to do the same for precious metals. Developments in bioleaching (recovering metals from e-waste using bacteria) and electrochemical recovery (separating metals via electrical currents) could help us strip gold, silver, and palladium from expired everyday gadgets.

As for the problem of tracking the world’s conveyor belt of e-waste and ensuring its proper disposal? What better than the ever-evolving Internet of Things (IoT), which can provide not just live monitoring of e-waste from drop-off to reprocessing, but also credible accountability for stakeholders along the value chain.

Any and all of these technologies, once their economic and environmental merits have been established, could be scaled-up and rolled-out widely. Assuming, that is, robust public-private investment in global regions which traditionally struggle to secure finance.

To improve the lives of people in emerging economies saddled with our e-waste, another partial answer looms: So far as our consumerist economic model allows, we could attempt to cut down on the number of new products we need.

Should electronic products be made to last longer?

Our accelerating consumption of electronic goods, coupled with generally inadequate e-waste treatment infrastructure, threatens to compound the e-waste problem in the years ahead. One response is to try to make our electronic goods last longer.

A study by the European Environment Agency (EEA) shows that, at present, smartphones, TVs, washing machines and vacuum cleaners are used for an average of 2.3 years less than their designed lifespan.[18] Conversely, the durability of other key products is actually improving over time. Between 2019 and 2023, for instance, the average operational period of smartphones increased by 5.1% (to four years and seven months); tablets by 7.5% (to five years and eight months); and televisions by 2% (to eight years and one month).[19]

Indeed, in the same way that prevention is better than cure medically, the best way of dealing with our e-waste problem could be to simply manufacture fewer electronics. Such a scenario will demand a multi-pronged strategy: Legislating to delay obsolescence; adhering to stricter eco-design principles; introducing binding right-to-repair regulations; and insisting on clearer ‘energy labelling’ to help nudge consumer choices.

Technology has transformed our lives for the better, and I am not alone in enjoying the daily benefits of my cellphone, smartwatch and tablet. Yet amid this world of digital distractions we must somehow keep our eyes on the bigger picture and appraise the long-term cost of our lifestyles.

After a certain point, large numbers risk becoming meaningless. To the human mind it is almost impossible to visualize the 62 million tons of e-waste we generated worldwide in 2022. It might be easier to reconsider the problem from an impact perspective: The mountains of toxic trash scarring the shorelines of developing nations, from which noxious gases rise to pollute our airstreams, and poisonous chemicals leach into our water table, the whole shameful dump endlessly picked over by individuals with limited life prospects.

It is a digital legacy that few of us would wish to leave to our children, and to our planet.

Tackling the e-waste problem: five fast facts

How much e-waste is generated annually?

The world generated 62 million tons of e-waste in 2022, the most recent data available. This comprised 31 million tons of metals, 17 million tons of plastics, and 14 million tons of other materials.

What percentage of global e-waste is actually recycled?

Less than a quarter (22.3%) of e-waste is successfully collected and recycled, with recycling rates expected to decline to just 20% by 2030.

How much valuable material is being wasted in discarded electronics?

Approximately US$ 91 billion worth of metals were dumped in e-waste in 2022 alone, including US$ 19 billion of copper, US$ 16 billion of iron, and US$ 15 billion of gold.

Who is most at risk from toxic e-waste exposure?

Around 18 million children and 13 million women worldwide face adverse health outcomes from e-waste recycling, often working without legal protection or proper training in low-middle income countries.

What are some potential solutions to tackle the e-waste crisis?

Solutions include stronger Extended Producer Responsibility laws, “right to repair” legislation, AI-powered sorting technology, new chemical recycling techniques, longer-lasting product design, and shifting focus from recycling to reuse and refurbishment.

[1] https://unitar.org/about/news-stories/press/global-e-waste-monitor-2024-electronic-waste-rising-five-times-faster-documented-e-waste-recycling

[2] https://www.who.int/news-room/fact-sheets/detail/electronic-waste-(e-waste)

[3] https://unitar.org/about/news-stories/press/global-e-waste-monitor-2024-electronic-waste-rising-five-times-faster-documented-e-waste-recycling

[4] https://ewastemonitor.info/wp-content/uploads/2024/12/GEM_2024_EN_11_NOV-web.pdf

[5] https://unitar.org/about/news-stories/press/global-e-waste-monitor-2024-electronic-waste-rising-five-times-faster-documented-e-waste-recycling

[6] https://ewastemonitor.info/wp-content/uploads/2024/12/GEM_2024_EN_11_NOV-web.pdf

[7] https://www.who.int/publications/i/item/9789240023901

[8] https://unitar.org/about/news-stories/press/global-e-waste-monitor-2024-electronic-waste-rising-five-times-faster-documented-e-waste-recycling

[9] https://unitar.org/about/news-stories/press/global-e-waste-monitor-2024-electronic-waste-rising-five-times-faster-documented-e-waste-recycling

[10] https://post.parliament.uk/research-briefings/post-pb-0045/

[11] https://unitar.org/about/news-stories/press/global-e-waste-monitor-2024-electronic-waste-rising-five-times-faster-documented-e-waste-recycling

[12] https://ewastemonitor.info/the-global-e-waste-monitor-2024/

[13] https://committees.parliament.uk/committee/62/environmental-audit-committee/news/200344/government-failing-to-grasp-fully-the-ewaste-tsunami-eac-questions-why-so-many-of-its-recommendations-accepted-by-ministers-are-not-being-consulted-on

[14] https://www.bbc.co.uk/news/articles/c51ep5583jyo

[15] https://unitar.org/about/news-stories/press/global-e-waste-monitor-2024-electronic-waste-rising-five-times-faster-documented-e-waste-recycling

[16] https://ewastemonitor.info/wp-content/uploads/2024/12/GEM_2024_EN_11_NOV-web.pdf

[17] https://www.cjdecycling.com/innovative-e-waste-recycling-technologies/

[18] https://www.circularonline.co.uk/news/lifespan-of-electronics-2-3-years-shorter-than-intended-by-design/

[19] https://www.eea.europa.eu/en/analysis/publications/product-lifespans-monitoring-trends

1x

1x

Added to press kit

Added to press kit