J-WAFS in Action: Providing safe, clean milk to rural communities

| Pranay Jain is a graduate student in mechanical engineering at MIT, working alongside Professor Sanjay Sarma in the Field Intelligence Laboratory. Pranay is part of a team, funded by the Abdul Latif Jameel Water and Food Security Lab (J-WAFS), that is developing a new low-cost handheld device to test milk quality and safety.

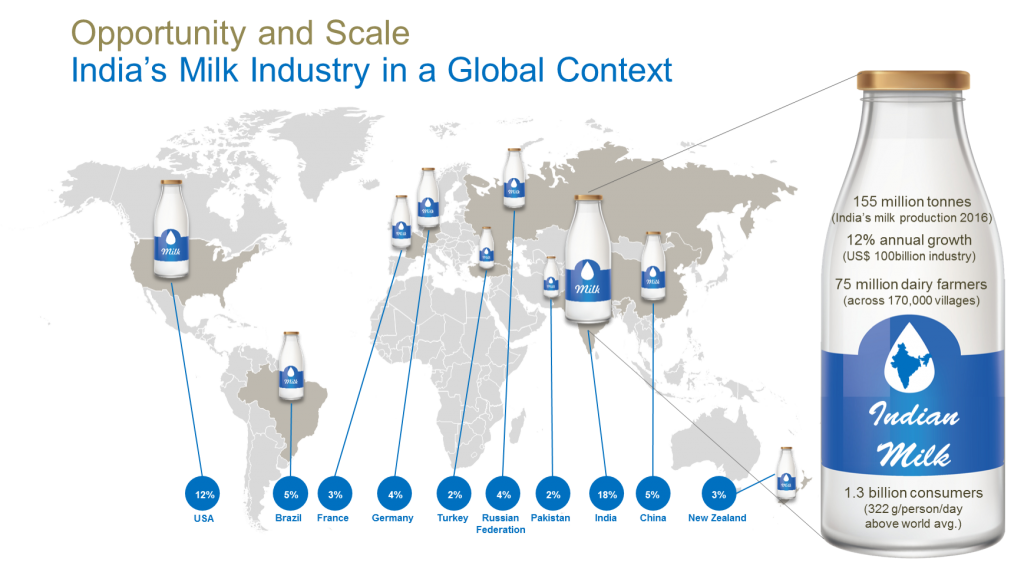

Opening Doors spoke to Pranay about the project and its aims. India is the world’s largest producer of milk, at over 150 million metric tons per year, or 18% of global output. This is 50% more than the United States and three times as much as China. Major dairy export markets include UAE, Pakistan and Bangladesh. Livestock distribution in India is much more equitable than land distribution. Some 75% of rural households own, on average, two to four animals and about a third of rural incomes are dependent on dairying. |

|

The dairy industry is characterized by millions of small farmers producing an average of five litres per day. So any improvement in the dairying environment can have a significant impact on millions of smallholder farmers, and on poverty reduction in general.

|

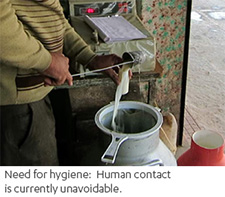

Only around one-quarter of the milk produced in India is tested for quality at source, however. Even then, the testing usually relies on out-of-date, unreliable equipment. And that’s a problem.

According to the World Health Organization, one in ten people fall ill every year from consuming contaminated food and 420,000 die as a result. Children under five years of age are at particularly high risk, with 125,000 children dying from foodborne diseases every year. |

What is the main issue you are trying to address with this project?

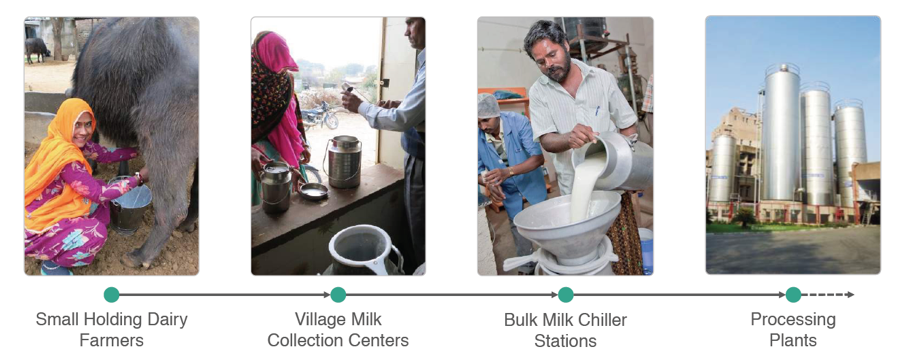

The supply chains common in milk production in India are long and complex, and this can often have a negative impact on quality and safety. Small-holder dairy farmers sell their milk to local dairy collection centers in the villages. It is then taken to regional collection centers, who sell it on further up the supply chain. Milk has to travel hundreds of miles and changes hands multiple times before it reaches processing plants or consumers.

The complexity of this supply chain and the lack of traceability, coupled with poor milk quality and contamination, have severely restricted the growth of the industry. It also creates severe quality and safety concerns among milk buyers, creates financial uncertainties for small-scale milk producers and poses a health risk to millions of consumers.

| What is the problem with current methods for testing milk quality?

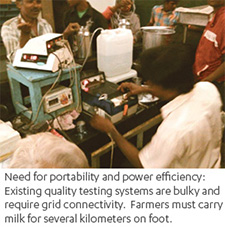

Current methods of testing milk are usually based on ultrasonic spectroscopy technology. This can be unreliable because ambient factors such as temperature and humidity can affect the readings. One day the equipment might say the milk has 4% fat, the next day it might say the same sample has 6% fat. This acts as a disincentive to farmers, who can’t be sure how much they will be paid for their milk. In contrast, our technology uses optical sensor technology to reliably test the quality of milk, by measuring milk fat and protein rapidly to estimate value, improve traceability, and enable real-time control. |

|

The device can then provide real-time measurements via a mobile phone device within one minute.

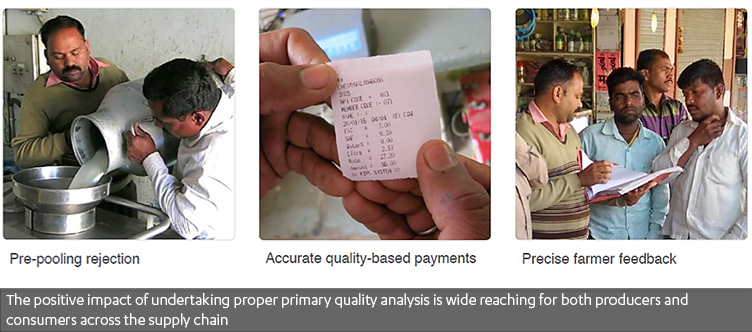

As well as improving quality control and traceability of the milk, it is beneficial for the farmers. If you have an instrument that can measure fat and protein accurately, you can have a high level of certainty that the milk is not tainted. So, if the farmer is using cattle which give a better yield, in terms of producing milk with a higher fat content, they get a better price for it, because fat content is one of the industry’s most important metrics. Fat and protein percentages also help to identify cattle health and any feed concerns, enabling precise farmer feedback.

Can you describe your proposed solution and how it works?

The technology uses a new spectroscopy method called Speckle Illuminated Diffusion Imaging to identify the particle size and volume fraction in the milk. It works by a small amount of milk being poured into a sampling cup on a handheld measuring device. An in-built optical sensor then detects particle concentrations in the liquid, which measure milk fat and protein.

The device projects light on the sample. It uses a special pattern to increase accuracy, and the milk reflects the pattern back to the sensor. The extent of blurring represents the properties of the liquid. By analyzing these images, we can estimate both fat and protein very accurately. The results are sent directly to a smartphone, so testing can be carried out in-situ and in real-time.

The reason we use an optical sensor is because the optical properties of milk do not vary when you change temperature or humidity. They are very consistent. Unlike ultrasonic sensors, which are affected by their environment.

| Are you confident this product can be developed at a low enough cost to be commercially viable in India?

To give you some perspective, the standard industrial-scale instruments that are used to measure the quality of milk at processing plants start at US$ 100,000 each. It is so high a price that you cannot scale it down to a collection center. That’s why collection centers are limited to using ultrasonic instruments, which cost around US$ 500 to US$ 800. We want to develop an instrument in that price bracket. As well as innovating in terms of technology, we are also trying to innovate with the business model. Currently, the collection centers bear the full cost of milk testing technology. But the data being collected at the collection centers is extremely useful for the processing plants. We want to try and monetize that data, so the ones who benefit from it – the processing plants – also contribute to collecting it. Are there other dense emulsions that this technology could be applied to? |

|

Yes, it could be applied to a wide variety of environments. We see these properties resonating in blood and other biological fluids. We see it in oil and gas and crude oil. It applies to wastewater. Anything that is dense and flowing. Even smoke coming out of a chimney. All these different colloids and emulsions have the potential for the technology to be used to measure their properties there and then, rather than sending off a sample to a lab. That’s very exciting.

Could it be applied to other markets, as well as India?

The technology is very transferable. It’s not limited to a particular problem or location. It will work perfectly well in most developing countries, whether in Africa, Asia or elsewhere. India is a great ‘test-bed’ when it comes to solving problems for developing countries that impact the rest of the world as well.

Your J-WAFS funding is for one year, until August 2018. Will your research be complete by then?

By August, we want to be at a stage where the technology and the scientific principles are fully proven. After that, we are at the translational stage to convert the technology into a viable product. That will probably take another year and will involve a lot of co-development work, particularly in India. That’s the next step.

How soon could we see the product brought to market?

My expectation right now is the end of 2019. That’s when we want an instrument not just in a pilot stage, but actually selling and being used in the industry. We want to pilot before that, early in 2019. Assuming that goes well, we aim to scale it up to commercial production by the end of that year.

Added to press kit

Added to press kit