The future is fusion

A Q&A with Commonwealth Fusion Systems’ Founder and CEO on its ground-breaking fusion technology program.

Commonwealth Fusion Systems (CFS) is one of the most exciting companies operating at the cutting edge of science and transforming thinking in the energy sector. Since being founded in 2018, as a spinout from MIT’s Plasma Science and Fusion Center it has been developing High-Temperature Superconducting (HTS) magnets and is building the world’s first net-energy-gain fusion system. This game-changing technology has the potential to provide the world with limitless, sustainable and clean power.

In December 2021, the JIMCO Technology Fund participated in CFS’s US$ 1.8 billion Series B funding round to accelerate the commercialization of fusion energy. The investment continues JIMCO’s support of innovative breakthrough technologies that will positively shape the future of core industries driving the global economy.

We spoke to Bob Mumgaard, Chief Executive Officer and Co-founder, CFS, and Fady Jameel, Deputy President and Vice Chairman, Abdul Latif Jameel, to discuss the company’s technology, its vision for truly sustainable energy and how it fits in with JIMCO’s fast-growing portfolio of advanced tech innovators and disruptors.

Can you explain the background to CFS and its mission?

BM: CFS was based on people and ideas that came out of the MIT Plasma Science and Fusion Center (PSFC). PSFC had been working on fusion energy for decades, and we could see that the technology was going to make the leap from lab to commercialization. The question was how that would happen and what we could do to speed the process along. In 2016, we started to formulate a plan, based on the advanced magnet technology we were developing at MIT, with whom we still work very closely. By 2018, CFS had spun out as a separate company and had its first funding. The next step was to execute the technical plan that we had put together.

Could you explain in simple terms the science behind fusion power systems?

Fusion is the opposite process of fission (also commonly known as nuclear fission, or what we know as nuclear power in daily life today). Whilst nuclear fission splits the atom, fusion takes the lightest atoms (for example, hydrogen) and combines them – or fuses them – together.

Fusion is the fundamental reaction of the universe. It’s how all stars – like our Sun – work. It’s the reaction that built up all the atoms inside us.

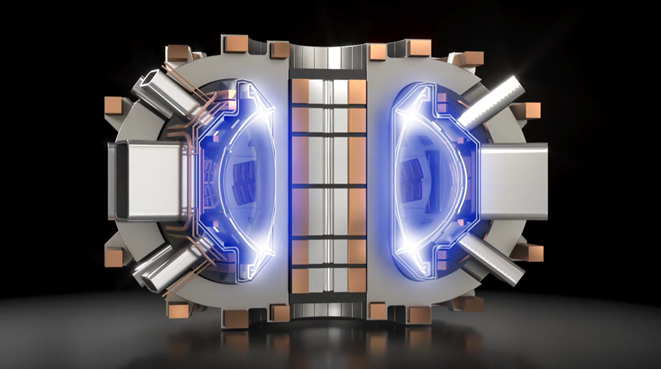

To make that reaction occur on Earth in a machine, you need to get the conditions inside that machine to replicate the conditions inside a star. That is very, very hot, like 100 million degrees [Celsius], so the material that produces fusion – plasma – feels like it’s in outer space, not on Earth. Most of the technologies that have been developed to do this use a magnetic field to insulate the plasma. The plasma is heated to incredible temperatures and eventually the reaction starts to happen and produces energy.

© courtesy of Massachusetts Institute of Technology (MIT) and the MIT Plasma Science and Fusion Center.

Two of the critical elements in enabling that process are the magnets and the size and shape of the machine. Basically, the stronger the magnets, the better the insulation. In terms of the machine, different shapes have different attributes to how the plasma is insulated. The type of machine most fusion energy systems use, including CFS, is called a tokamak, which is basically a ‘magnetic bottle’ for confining fusion plasma.

So what is so ground-breaking about fusion energy?

BM: The fusion process releases enormous amounts of energy – around 200 million times more energy per reaction than burning fossil fuels.

Illustration © courtesy of EUROfusion / US Dept. of Energy.

This has a whole bunch of knock-on effects. One, it means that basically the fuel is free. There is no resource that’s required for the fuel. It’s everywhere and is universally accessible.

This means that energy is decoupled from resources, which is a fundamental shift in how we think about energy and power. You’re not extracting something from the ground or waiting for the wind to blow or the sun to shine. You’re just building a machine.

The other thing is, because it’s the opposite of nuclear [fission] power, it doesn’t have the downsides. It doesn’t have the atomic chain reaction or the meltdown concerns. It doesn’t have the materials you have to keep track of because they can be used to make weapons. It doesn’t have the long-lived nuclear waste that needs to be disposed of. It’s a much cleaner, simpler process in that sense.

Was there a particular technological breakthrough that you saw as a way to push forward this technology?

BM: Yes, there was. The tokamak is by far the most understood approach to fusion. It’s a proven to confine the plasma in which fusion occurs and is higher performing than any other concept by a factor of around 1,000.

There is one big downside, though: current tokamak technology requires them to be very large to create the magnetic field to achieve net energy for fusion, a requirement for a power plant. For example, an international collaboration of countries is building one in the south of France called ITER and it is a very, very big facility. The platform for the tokamak machine alone is 1km long and 400m wide – equivalent to about 60 soccer fields.

We believed if we could build more powerful magnets with a significantly higher magnetic field, we could drastically reduce the size of the tokamak and achieve net energy from fusion with a smaller and less expensive machine.

So, we used newly available high-temperature superconductors (HTS) to build new game-changing magnets that were much smaller with much higher magnetic fields than current fusion magnets.

As a result, by developing these HTS magnets in the right configurations, we can now make much, much smaller tokamaks – about 40 times smaller than ITER, for example – which is a game-changer for fusion systems.

How powerful are these HTS magnets?

BM: The magnets we use are 20 Tesla[1] (20T), which is the unit used to measure magnetism. This is the strongest fusion magnet of its kind. By comparison, a 15T magnet could lift 31 Eiffel Towers, a 19T magnet could lift 403 Boeing 747s, and our 20T magnet could lift a battleship.

Were these HTS magnets developed at MIT?

BM: When we started there were very few HTS magnets. Some of the material had been around, and people had made smaller magnets out of it, but nothing anywhere close to what was needed for a fusion machine.

At the start of CFS as a company our objective was focused on how we develop this magnet technology as quickly as possible. That was our goal for the first three years of the company, in collaboration with MIT. People said it would take at least 10 years. We were confident we could do it in three, and we did.

Fady, Abdul Latif Jameel has a long track record in investing in sustainable energy technologies. What is it about Commonwealth Fusion Systems that particularly grabbed your attention?

FJ: We first became aware of CFS through our relationship with MIT. MIT is very close to our hearts and our business, and we take what they say very seriously. It’s been quite a successful relationship in terms of business, and also in terms of philanthropy.

When we heard about CFS we were immediately interested due to our existing involvement in renewable energy technologies, both in solar and wind, and most recently in green hydrogen. CFS is pioneering a transformational pathway that could help to enable global decarbonization at a much faster rate through its revolutionary technology, and we were keen to get involved and provide our support to aid and accelerate that process.

I was with our Chairman in Glasgow at COP26, and we saw the level of interest in fusion energy. It’s generating a lot of excitement in terms of what could be achieved, possibly much sooner than other available technologies today.

Do you think private capital has an opportunity, if not a responsibility, to accelerate the development of breakthrough technologies like this and create a sustainable future?

FJ: Yes. I think private capital – and family businesses – both have the advantage of patience. They can afford to invest for the longer term because they don’t have a raft of shareholders demanding returns in three to five years. As such, I believe they have a unique opportunity, arguably a responsibility, to invest in these types of breakthrough future technologies as part of their business continuity, and also as a responsibility for future generations.

There are other fusion energy projects being worked on around the world. What makes CFS’s technology different? Is it all about the magnets?

BM: Our aim is to move fusion technology forward as fast as possible by using the proven science and developing new technologies that will enable commercialization.

That’s why we use the tokamak – it’s the highest-performing and most well-understood fusion approach. Then we add the thing that was missing, which was the ability to build it in the right scale, and that comes from the HTS magnets. By adding HTS magnet technology to tokamaks, we are able to commercialize fusion energy on the fastest possible timeline.

It’s not only our magnet technology that makes CFS unique. We’re very much a collaborative group. We work collaboratively across different labs and institutions. We publish our research, get peer reviewed, ask questions. We are constantly asking, “How can we make this better?” The level of critique we invite is fairly unique. We do that because we know this approach has been proven in industry, over and over again, as a way to accelerate progress, to get things out into the world faster. With climate change, we’re dealing with a ticking clock, so we want to move as fast as we can.

Once it’s commercialized, will this technology replace solar and wind energy, or will it complement them?

BM: It’s very clearly a complement. Energy is the largest market in human history, but we have to completely change how we do it. It is a daunting task, but that is what the energy transition requires.

We should be deploying the technologies that we have today as fast as we can, so wind and solar, those are technologies that we have today. They’re not perfect, but they’re way better than putting more carbon in the air. If you don’t solve the energy question, you don’t solve climate change.

Fusion offers the ability to have another complementary tool that is zero-emissions, with zero carbon, no resource extraction, no high-level nuclear waste, and very, very power dense, meaning it makes a lot of power in a small plant. That’s a very unique thing to put into the energy mix.

Bob, you talk about being ready to commercialize fusion energy by the early 2030s. What are the next steps towards achieving that?

BM: Our first milestone was to build the HTS magnet and show that it could work. We just finished that in September [2021]. The next milestone is to build and operate SPARC. SPARC is a commercially relevant net-energy fusion tokamak that uses HTS magnet technology. It will be the first net-energy tokamak that has ever been built, which means much more power comes out than goes in to heat the plasma. SPARC is designed to produce 10 times more power than it consumes, which is what you need for a commercial system, and we’re aiming to do that in 2025.

SPARC itself does not put power on the grid. We are building another system to do that, the first fusion power plant we call ARC.

SPARC is already under construction and should be operating in 2025. It will hugely advance our understanding not the plasma physics and a tokamak, but also the experience of building the plant and what it costs. It will give us a lot of confidence on how the commercial unit, ARC, will work. From SPARC we will learn more about how it will run, what it will cost, and what it will take to put that onto the grid. We’re aiming to have ARC up and running in the early 2030s.

What are you most looking forward to over the next few years as CFS works towards its goals?

FJ: We’re very excited and we’re looking forward to the journey together.

We’re here to help. We’re here to really push this forward. This is much more to us than just a profitable venture.

This is a new direction for JIMCO, and hopefully a new direction for the industry and for our society.

BM: We are already well on our way on that journey. We are out there doing this right now. We’re excited. We’re confident. In the past, we have always had ambitious timelines and we’ve done a pretty good job of hitting those timelines even in the face of skepticism. We’re excited to continue to do that going forward, picking up momentum, working with more partners, paving the way in the future so that the next stage is ready.

[1] The Tesla (T) is a derived unit of the magnetic B-field strength in the International System of Units. One tesla is equal to one weber per square meter. 1 T in: is equal to SI base units: 1 kg⋅s−2⋅A−1 Symbol: T Derivation: 1 T = 1 Wb/m2

1x

1x

Added to press kit

Added to press kit